Nd-Fe-B magnets refer to intermetallic compounds composed of rare earth element Nd and iron and boron. Nd is mainly the combination of neodymium or neodymium with other rare earth elements, and sometimes some iron is replaced by cobalt, aluminum, vanadium and other elements. With the development of computer, communication and other industries, the rare earth permanent magnet industry, especially NdFeB permanent magnet industry, has developed rapidly. Rare earth permanent magnetic material is one of the most comprehensive permanent magnetic materials known.

NdFeB magnets can be divided into bonded NdFeB magnets and sintered NdFeB magnets. The difference between the two is mainly in the process. Bonded NdFeB is formed by injection molding of NdFeB magnetic powder with adhesive, while sintering is formed by vacuuming and heating at high temperature. The sintered NdFeB permanent magnet material adopts the powder metallurgy process. The melted alloy is made into powder and pressed into a pressing embryo in the magnetic field. The pressing embryo is sintered in inert gas or vacuum to achieve densification. In order to improve the coercivity of the magnet, aging heat treatment is usually required.

Bonded NdFeB magnets are magnetic in all directions and corrosion resistant; However, sintered NdFeB has poor corrosion resistance and is extremely easy to oxidize. The surface needs to be coated with zinc, nickel, environment-friendly zinc, environment-friendly nickel, nickel-copper nickel, environment-friendly nickel-copper nickel, etc; Sintered NdFeB is generally divided into axial magnetization and radial magnetization, which can be determined according to the required working face.

The grade of sintered neodymium iron boron is also called brand. NdFeB magnets have a variety of brands to choose from. All brands start with the letter "N", representing neodymium. For example, N35, N38, N40, N42, N45, etc. Grade is a good indicator of magnet strength. In short, the higher the grade of the magnet, the greater the magnetic field generated by the magnet, which means the greater the magnetic field of the magnet.

NdFeB magnets are not actually high-temperature magnets, but they have high temperature resistance. Some special grade materials can withstand higher temperatures than ordinary Nd magnets.

The high temperature resistance grade is indicated by the letter at the end of the magnet grade. These letters represent the temperature rating and maximum operating temperature that the magnet can withstand before it begins to lose its magnetism permanently. For example, N35SH, SH represents temperature resistance of about 150 ℃. UH and EH can reach a temperature resistance of about 180 ℃.

The NdFeB permanent magnet has little effect on the magnet itself at a low temperature of - 60℃. The low temperature environment will also increase the paramagnetism of the magnet itself and enhance its electronic layout stability. Magnetic materials are more favorable for their operation in low temperature environment than in high temperature environment. Neodymium magnets can also play a role in negative 130 ℃ working temperature, but the magnetic direction will move and the magnetic properties will be reduced by 15%.

The permeability of NdFeB rare earth magnets is very low because they have strong magnetic dipoles that resist external magnetic fields. This means that these magnets are strongly resistant to external magnetic fields, which means that they will not easily reorient their magnetic domains when affected by external magnetic fields. NdFeB magnets also have high coercivity, which makes them difficult to demagnetize. Low permeability materials are usually used as permanent magnets, while high permeability materials are used as soft magnetic materials.

Sintered NdFeB magnets are prone to oxidation and corrosion, requiring surface treatment. According to the different requirements of the use environment, surface treatment methods such as phosphating, electroplating, electroless plating, electrophoresis and vapor deposition can be used. Commonly used coatings include zinc, nickel, nickel, copper and nickel, epoxy resin, etc.

The application of NdFeB magnets in electrical appliances is very special, just like in electric motors. NdFeB magnets are made of a mixture of iron, boron and neodymium. Their resistance and diversity of production methods make them very common in daily life, so that we can find them in almost any field.

As far as electrical appliances are concerned, NdFeB magnets are basically used for audio equipment such as speakers, earphones and microphones. For example, the speaker is controlled by two magnets and a current. The movable electromagnetic coil is suspended near a fixed magnet, and the current quickly passes through the coil.

When the coil is electrified, it will be attracted by the magnet and repelled again, causing the vibration to be amplified and become music on your ear. The microphone works in a similar principle, of course, because when the coil moves in the magnetic field generated by neodymium magnet, it will generate electrical signals and reproduce itself in the form of sound.

In addition to loudspeaker, neodymium iron boron magnets are also often used in electric motors, sensors, inductors, etc.

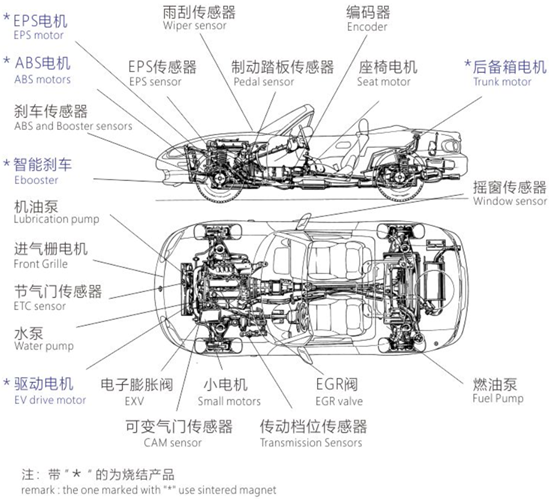

Neodymium magnet (neodymium iron boron) is an important component in automobile electronic technology. It has a wide range of applications in automobile safety and information system, electronic control unit, automobile multimedia system, energy transmission system, etc.

With the development of new energy vehicles and driverless technology, various safety control systems such as safe driving assistance system and collision prediction system will be developed and widely used, and the global automotive electronics industry has ushered in a golden period of development. In this market, innovation is highly valued, new products and new applications continue to emerge, and automotive electronic technology is changing the face of the entire automobile.

Magnetic components used in automobile electronic technology are mainly made of neodymium magnets, soft magnetic ferrite materials and metal soft magnetic materials. With the development of lightweight, intelligent and electrification of automobiles, the requirements for magnetic materials are becoming higher and higher.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China