Magnets are substances or materials that can produce magnetic fields. The property that an object can attract iron, cobalt, nickel and other substances is called magnetism. Objects with magnetism are called magnets. It has an invisible force that can attract and repel some substances. It is generally divided into permanent magnets and soft magnets.

Permanent magnetic materials, also known as hard magnetic materials, refer to magnetic materials that can retain their strong magnetism for a very long time after being magnetized by some external magnetic fields, and have high coercivity. Permanent magnetic materials are the earliest discovered and applied magnetic materials by human beings. At the same time, they are also a wide variety of magnetic materials with rapid development and wide application.

Permanent magnetic materials, also known as hard magnetic materials, usually have a high coercivity, and its coercivity HC is generally not less than 10A4/m. Once magnetized, it has a high magnetic energy product, and has a high stability to maintain magnetism when disturbed by external magnetic field, temperature and vibration.

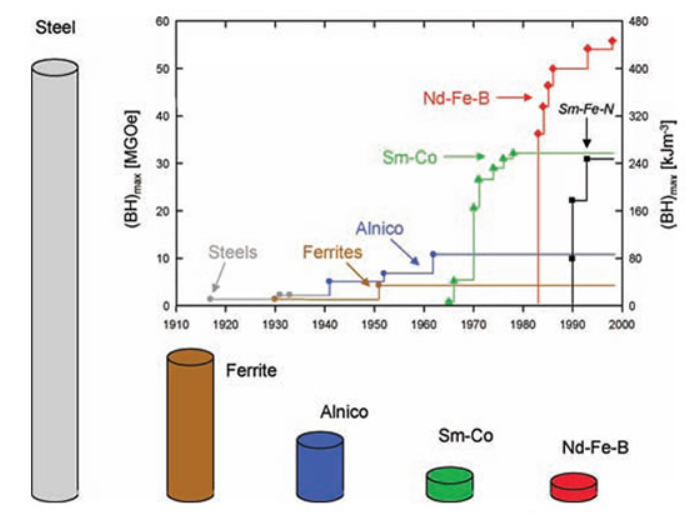

AlNiCo permanent magnet alloy

With iron, nickel and aluminum as the main components, it also contains copper, cobalt, titanium and other elements. It has high remanence and low temperature coefficient, and magnetic stability. There are two kinds of casting alloy and powder sintered alloy. It was widely used in the 1930s and 1960s, and is now mainly used in the manufacturing of magnetoelectric instruments, flow meters, micro and special motors, relays, etc. in the instrument industry.

FeCrCo permanent magnet alloy

With iron, chromium and cobalt as the main components, it also contains molybdenum and a small amount of titanium and silicon. It has good processing performance and can be subject to cold and hot plastic deformation. Its magnetism is similar to AlNiCo permanent magnetic alloy, and its magnetic properties can be improved through plastic deformation and heat treatment. It is used to manufacture various small magnetic components with small cross-section and complex shape.

Ferrite permanent magnet

They mainly include barium ferrite and strontium ferrite, which have high resistivity and high coercivity, and can be effectively applied in the magnetic circuit of the atmospheric gap, especially suitable for permanent magnets of small generators and motors. Permanent magnet ferrite does not contain precious metals such as nickel and cobalt. It has rich sources of raw materials, simple process and low cost. It can replace AlNiCo permanent magnets to manufacture magnetic separators, magnetic thrust bearings, loudspeakers, microwave devices, etc. However, its maximum magnetic energy product is low, its temperature stability is poor, its texture is brittle and fragile, and it is not resistant to impact and vibration. It is not suitable for measuring instruments and magnetic devices with precision requirements.

Rare earth material

They are mainly rare earth cobalt permanent magnetic materials and neodymium iron boron permanent magnetic materials. The former is an intermetallic compound formed by rare earth elements such as cerium, praseodymium, lanthanum, neodymium and cobalt. Its magnetic energy product can reach 150 times of carbon steel, 3-5 times of AlNiCo permanent magnetic material, and 8-10 times of permanent magnetic ferrite. The temperature coefficient is low, the magnetic stability is stable, and the coercivity is up to 800 kA/m. It is mainly used for magnetic systems of low-speed torque motors, starting motors, sensors, magnetic thrust bearings, etc. NdFeB permanent magnetic material is the third generation of rare earth permanent magnetic material. Its remanence, coercivity and maximum magnetic energy product are higher than the former. It is not fragile, has good mechanical properties, and has low alloy density, which is conducive to the lightweight, thinness, miniaturization and ultra-miniaturization of magnetic components. However, its high magnetic temperature coefficient limits its application.

Compound material

It is composed of permanent magnetic material powder and plastic material as binder. Because it contains a certain proportion of binder, its magnetic properties are significantly lower than the corresponding magnetic materials without binder. In addition to metal composite permanent magnet materials, other composite permanent magnet materials are limited by the heat resistance of the adhesive, and the service temperature is relatively low, generally not more than 150 ℃. However, the composite permanent magnet material has high dimensional accuracy, good mechanical properties, and good uniformity of the performance of all parts of the magnet, so it is easy to conduct the radial orientation and multi-pole magnetization of the magnet. It is mainly used for manufacturing instruments and meters, communication equipment, rotating machinery, magnetic therapy equipment and sporting goods.

Soft magnetic materials refer to magnetic materials with low coercive force and easy to magnetize and demagnetize. Compared with permanent magnetic materials, soft magnetic materials have high permeability, and can obtain large magnetic induction strength and high density magnetic flux under low external magnetic field strength. At the same time, the coercivity is small, and it is easy to demagnetize after removing the magnetic field. In practical applications, soft magnetic materials mainly play the role of magnetic conduction, realizing the transformation of electrical energy parameters of the circuit, and are applied to transformers, relays, inductor cores, relays and speaker magnetic conductors, magnetic shields Motor stator rotor and many other fields. At present, soft magnetic materials mainly include ferrite soft magnetic materials, metal soft magnetic materials and other soft magnetic materials.

Ferrite soft magnetism

Ferrite soft magnetism is a ferrimagnetic oxide mainly composed of Fe2O3. Because soft magnetic ferrite has high permeability, high resistivity, low loss and other characteristics at high frequency, and has batch production, stable performance and high mechanical processing performance, it can be made into magnetic cores of various shapes using molds, and the cost is low. The products are widely used in communication, sensing, audio and video equipment, switching power supply and magnetic head industry.

Metal soft magnetism

Metal soft magnetic materials mainly include industrial pure iron and traditional alloys (mainly silicon steel sheets), metal magnetic powder cores, amorphous and nanocrystalline alloys.

Silicon steel is a ferrosilicon soft magnetic alloy with very low carbon content. The addition of silicon can improve the resistivity and maximum permeability of iron, reduce the coercivity, core loss (core loss) and magnetic aging. It is mainly used as the core of various motors and transformers. It is cheap and suitable for large-scale production. It is an essential soft magnetic alloy in power, electronics and military industries.

Metal magnetic particle core is made of metal alloy powder with low loss under high frequency conditions. Due to the uniformly distributed air gap inside the magnetic particle core, it does not leak magnetic flux and is not easy to be saturated under high DC current. The metal magnetic powder core combines the advantages of metal and ferrite soft magnetic materials, its resistivity is significantly higher than that of soft magnetic metal, can effectively reduce eddy current loss, and has higher saturation magnetization than soft magnetic ferrite, and can better meet the requirements of miniaturization and integration of power electronic devices.

Amorphous alloy materials are currently mainly used in the field of distribution transformers to replace silicon steel materials. The distribution transformer can be divided into silicon steel transformer and amorphous transformer according to the different raw materials used for the core of the core. The main raw materials used for the two are silicon steel sheet and amorphous alloy strip. Compared with silicon steel transformer, amorphous transformer has obvious advantages in energy saving and efficiency improvement. It is a recyclable green product in the whole life cycle of "manufacturing energy saving, using energy saving, recycling energy saving".

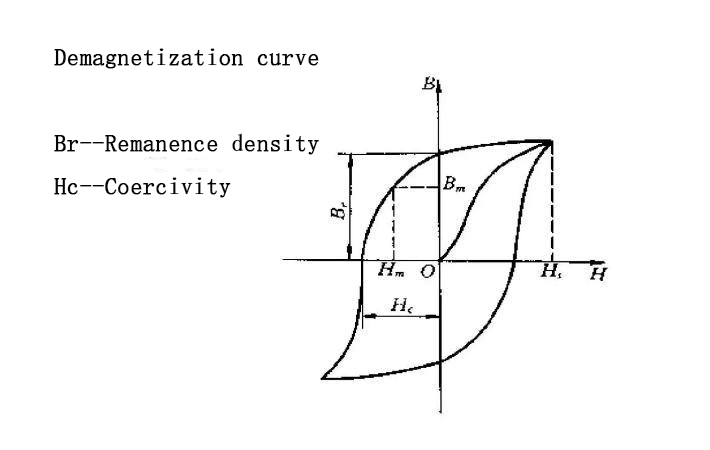

The remanent magnetic induction intensity refers to the magnetic induction intensity of the magnet when the external magnetic field is removed after a magnet is magnetized to the technical saturation in a closed circuit environment by the external magnetic field. It is called the remanent magnetic induction intensity, which is expressed by the English symbol Br. The unit of remanence is Tesla (T) or Gauss (Gs), and the conversion relationship is 1T=10000 Gs.

Coercive force refers to the magnetic material's magnetic induction strength B does not return to zero when the external magnetic field returns to zero after saturation magnetization. Only by adding a certain amount of magnetic field in the opposite direction of the original magnetization field can the magnetic induction strength return to zero. This magnetic field is called coercive field, also called coercive force. The higher the value of coercivity, the better the temperature resistance. The coercivity can be divided into magnetically induced coercivity (Hcb) and intrinsic coercivity (Hcj).

Magnetic coercivity

When the magnet is magnetized in the reverse direction, the value of the reverse magnetic field intensity required to reduce the magnetic induction intensity to zero is called the magnetic induction coercivity (Hcb). But at this time, the magnetization of the magnet is not zero, but the added reverse magnetic field and the magnetization of the magnet cancel each other. (The external magnetic induction strength is zero) At this time, if the external magnetic field is removed, the magnet still has certain magnetic properties.

Intrinsic coercivity

The intensity of the reverse magnetic field applied when the sum of the microscopic magnetic dipole moment vector inside the magnet is reduced to 0 is called the intrinsic coercivity (Hcj). The intrinsic coercivity is different from the coercivity (Hcb). When the reverse magnetic field H=Hcb, although the external magnetic induction intensity is zero, the residual magnetization (Br) of the magnet itself is not zero, but the added reverse magnetic field and Br cancel each other. When the reverse magnetic field H=Hcj, the residual magnetization of the magnet decreases to 0.

The product of B and H at any point on the (BH) max demagnetization curve, i.e. Bm, Hm and (BH), represents the magnetic energy density established by the magnet in the air gap space, i.e. the magnetostatic energy per unit volume of the air gap. Since this energy is equal to the product of the magnet Bm and Hm, it is called the magnetic energy product. The relationship curve of the magnetic energy product changing with B is called the magnetic energy curve. The product of Bd and Hd corresponding to one point has the maximum value, which is called the maximum magnetic energy product. It is one of many magnetic parameters, and its direct industrial significance is that the larger the magnetic energy product, the less magnetic materials are required to produce the same effect.

It is generally impossible for instruments and equipment made of permanent magnetic materials to work at a constant temperature, and the change of ambient temperature has a direct impact on the magnetic properties of the magnet. In order to make the instruments and equipment work normally when the temperature changes, it is necessary to know the change of the magnetic properties of the magnet with the temperature when designing the magnetic circuit.

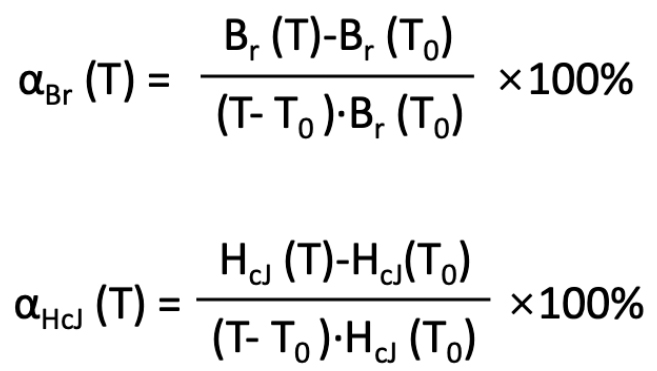

In order to quantitatively reflect the influence of temperature on the performance of magnets, people have defined some temperature stability parameters related to ambient temperature, such as remanence temperature coefficient α Br, intrinsic coercivity temperature coefficient α HcJ, reversible loss Lrev and irreversible loss Lirr of open-circuit magnetic flux density, reversible temperature coefficient of open-circuit magnetic flux density, heat-resistant temperature or maximum continuous working temperature Tm, etc., wherein the residual magnetic temperature coefficient α Br, intrinsic coercivity temperature coefficient α HcJ is one of the performance indicators that commercial permanent magnets must provide.

Temperature coefficient of remanence and intrinsic coercivity

The temperature coefficient, as the name implies, is the relative change rate of physical quantity with temperature. From the reference temperature T0 to a certain temperature range of high temperature T, the residual temperature coefficient and the intrinsic coercivity temperature coefficient are defined as follows, with the unit of%/℃.

There are many kinds of permanent magnet materials, and their properties vary greatly. Therefore, when designing permanent magnet motor, it is necessary to select the appropriate permanent magnet materials and specific performance indicators.

It shall be able to ensure that there is enough air gap magnetic field and specified motor performance index in the air gap of the motor.

The stability of magnetic performance shall be guaranteed under the specified environmental conditions, working temperature and service conditions.

It has good mechanical properties and is convenient for processing and assembly.

Better economy and appropriate price.

The actual magnetic properties of permanent magnet materials are related to the manufacturer's specific manufacturing process, and their values often deviate from the data specified in the standard. The magnetic properties of permanent magnet materials of the same brand, different manufacturers or different batches of the same manufacturer are different.

The capacity and magnetization method of the magnetizer will affect the uniformity and magnetic performance of the magnetization state of the permanent magnet. Therefore, in order to improve the accuracy of motor design and calculation, it is necessary to ask the manufacturer for demagnetization curves of this batch of actual size permanent magnets at room temperature and operating temperature. It is better to directly sample and measure demagnetization curve when conditions permit, which is safer.

The magnetism of permanent magnetic materials is not only related to alloy composition and manufacturing process, but also related to magnetic field heat treatment process. The so-called magnetic field heat treatment refers to the application of an external magnetic field in the decomposition reaction of permanent magnetic materials. After magnetic field heat treatment, the magnetic properties of permanent magnetic materials are improved, with directionality. The direction of the paramagnetic field is the largest, and the direction of the vertical magnetic field is the smallest, which is called anisotropy. For permanent magnetic materials without magnetic field heat treatment, magnetism has no directionality, which is called isotropy. It should be noted that for anisotropic permanent magnets, the magnetic field direction during magnetization should be consistent with the magnetic field direction during magnetic field heat treatment, otherwise the magnetic properties will decline.

When the permanent magnetic material rises from the room temperature to the maximum working temperature, it is allowed to have an irreversible loss of no more than 5% of its open circuit magnetic flux after cooling to the room temperature after holding for a certain time. Therefore, in order to ensure the stable performance of the permanent magnet motor during operation and avoid obvious irreversible demagnetization, the permanent magnet should be stable before use.

In the long-term development process, the application of permanent magnetic materials has penetrated into all aspects of the national economy and national defense, and the new energy vehicle is one of them. With the development of automobiles in the direction of miniaturization, lightweight and high-performance, the performance requirements of the magnets used are increasingly increasing, promoting the development and application of permanent magnet materials.

Rare earth permanent magnetic material is a kind of magnetic material made of samarium and neodymium mixed rare earth metals and transition metals (such as cobalt, iron, etc.), which are pressed and sintered by powder metallurgy method and magnetized by magnetic field. Compared with traditional permanent magnetic materials, rare earth permanent magnetic materials are currently the magnetic materials with the best magnetic properties and comprehensive performance, and have become an indispensable key basic material for modern industry.

China is rich in rare earth resources and has become the world's largest production base and export base of rare earth permanent magnet materials. The rare earth permanent magnet industry has strong competitiveness in the world.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China