SmCo magnet is a kind of rare earth magnet. It is a kind of magnetic tool material made of samarium, cobalt and other metal rare earth materials by mixing, melting and refining into alloys, and then crushing, molding and sintering. It has high magnetic energy product and extremely low temperature coefficient. The maximum working temperature can reach 350 ℃, and the negative temperature is unlimited. When the working temperature is above 180 ℃, its maximum magnetic energy product The coercivity, temperature stability and chemical stability are higher than those of NdFeB permanent magnetic materials.

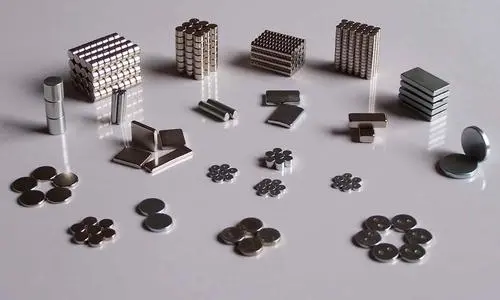

According to the molding process, SmCo can be divided into two forms: sintering and bonding.

Fine SmCo magnetic powder is pressed in the mold and then sintered, and the magnetic powder is refined into solid material. There are two forms of pressing: mold pressing (placing magnetic powder in a solid mold for pressing), and isostatic pressing (placing magnetic powder in a special "rubber" mold, pressing with the same force from all directions). The product pressed by die is smaller than that by isostatic pressing. Although the magnetic properties of the products produced by isostatic pressing are higher, the consistency of the magnetic properties is generally worse than that produced by die pressing. Sintered products usually require machining to meet the required tolerances.

Bonding SMCO is a production process that uses a special SmCo magnetic powder and plastic binder to mix, press and heat treat. The products produced by this process can reach complex shapes and highly precise dimensions without subsequent processing.

SmCo1:5 magnet, also known as SmCo5, has a maximum operating temperature of 250 ℃. The blank with different properties and grades is made from metal samarium, cobalt and praseodymium by melting, milling, pressing, sintering and other processes.

SmCo5 has better physical properties and ductility than Sm2Co17, so SmCo5 is easier to process thin wall or ring wall, and its shape is complex, while Sm2Co17 is brittle. The magnetic field of SmCo5 is smaller than Sm2Co17. In general, SmCo5 can be magnetized by 4000Gs of magnetic field saturation, while Sm2Co17 magnetization with Hcj value needs more than 6000Gs of magnetic field.

The metal cobalt content of SmCo5 is higher than Sm2Co17, so its price is higher than Sm2Co17. Users can reasonably select SmCo5 or Sm2Co17 according to different use environments. For information about the performance grade of SmCo5, see the SmCo magnet performance parameter table.

SmCo2:17 magnet, also known as Sm2Co17, has a maximum operating temperature of 350 ℃. The blank with different performance grades is made by continuous casting of metal samarium, cobalt, copper, iron, zirconium, etc. in proportion, and processed by a series of processes such as melting, milling, pressing, sintering, etc.

Sm2Co17 has extremely low temperature coefficient and good corrosion resistance. At high temperature, its magnetic properties are better than NdFeB magnets, so it has been widely used in aerospace, national defense, sensors and other fields.

Due to the large brittleness of Sm2Co17 material, it is not suitable for occasions with complex shape and thin disk or ring wall. Due to this characteristic, appearance defects such as small chips may appear during production, testing and magnetization. However, it will not change its nature. We consider them as qualified products.

High magnetic properties (high remanence, high coercivity, high magnetic energy product). The magnetic properties of SmCo magnets at room temperature reach 35MGOe, which is only lower than that of NdFeB magnets and far higher than other magnets.

The maximum service temperature is 550 ℃, which is the highest of all magnets.

With strong corrosion resistance and oxidation resistance, the magnet can be used for a long time without surface corrosion treatment.

Extremely low temperature coefficient, generally -0.030%/K.

In the Nd-Fe-B permanent magnet, the rare earth metal neodymium accounts for about 29%~32.5%, the metallic element iron accounts for 64%~69%, and the non-metallic element boron accounts for 1.1%~1.2%. In addition, a small amount of dysprosium, terbium, niobium, copper and other elements are added.

SmCo magnet, for example, 2:17 type, rare earth metal samarium accounts for 23%~28%, metal cobalt accounts for 48%~52%, metal element iron accounts for 14%~17%, and a small amount of copper, zirconium and other elements.

The overall magnetic property of SmCo permanent magnet is lower than that of neodymium iron boron permanent magnet. In addition, SmCo magnets with the same performance size are slightly more expensive than neodymium iron boron magnets. It can be seen from the proportion of metal elements between the two that the content of iron in neodymium iron boron is the highest, while the content of samarium and cobalt in SmCo magnets accounts for about 70%.

The working temperature of NdFeB permanent magnet is between 80 ℃ and 200 ℃, while the working temperature of SmCo permanent magnet can reach 250 ℃~350 ℃.

NdFeB magnets have high iron content, so they are easy to be oxidized and corroded. The surface treatment process is essential. The service life of the magnets depends largely on the effect of the coating.

SmCo magnets consist of about 65% cobalt. Cobalt is the main component of stainless steel, so it is easy to see that cobalt is an important reason for the excellent corrosion resistance of SmCo magnets. Cobalt is one of the three natural ferromagnetic elements besides iron and nickel. Generally, surface treatment is not required, unless the working environment is relatively bad or electroplating is required to beautify the appearance.

The (Br) temperature coefficient of SmCo magnet is only -0.03-05%/℃. It is much smaller than the -0.11%/° C value of NdFeB. This means that compared with NdFeB, SmCo loses less field strength per 1 degree temperature increase. This makes it easier for engineers to adjust the temperature effects, because these effects are smaller in a larger temperature range.

The temperature coefficient of SmCo is about 0.20-0.30%/° C. The temperature coefficient of NdFeB is 0.45-0.60%/° C. The two things that cause magnets to demagnetize are high temperature and high antimagnetic field. By this measure, SmCo magnet is much better than NdFeB magnet - especially at high temperature.

SmCo and NdFeB can be made into very strong magnets. The biggest difference is the optimal temperature of each magnet

NdFeB magnet is the strongest permanent magnet available at room temperature and up to about 180 ℃ - measured by its remanence (Br). But as the temperature rises, their strength will drop rapidly. With the working temperature approaching 180 ℃, the performance of SmCo magnet begins to be better than that of neodymium iron boron.

There are many overlaps between the two materials, but it is obvious that NdFeB performs well at lower temperatures, while SmCo performs well at higher temperatures.

SmCo permanent magnetic materials have been widely used in the magnetic field. Their characteristics include high coercivity, high magnetic energy product, low temperature coefficient and excellent corrosion resistance. These characteristics make SmCo permanent magnetic materials have important applications in many fields, such as motors, electronics, magnetic sensors, medical equipment, etc. One of the most important fields is electric motor.

In the field of motors, SmCo permanent magnet materials are widely used in various types of motors, such as permanent magnet synchronous motors, DC motors, stepping motors, etc. Compared with traditional motors, the use of SmCo permanent magnet materials in permanent magnet motors can greatly improve the efficiency and power density of the motor, which has greater advantages in achieving high efficiency and miniaturization. Therefore, SmCo permanent magnet materials are widely used in modern electric vehicles, high-speed trains and new generation wind turbines.

In addition, SmCo permanent magnetic materials have been widely used in various magnetic sensors because of their excellent properties such as high coercivity and high magnetic energy product. For example, in the automobile ABS system, the magnetic sensor made of SmCo permanent magnetic material can detect the rotational speed and position of the wheel in real time, thus helping the automobile achieve more accurate braking and control.

In short, the excellent properties and wide application of SmCo permanent magnetic materials make it play an important role in rare earth materials. Although there are problems in the supply of rare earth resources in the world at present, with the continuous development of science and technology, it is believed that more technologies and means will be developed to better utilize and develop rare earth resources.

At present, the market of SmCo permanent magnetic materials is in a stage of rapid development. From the perspective of policy, with the increasing support of the state for the new energy vehicle industry, the market demand for SmCo permanent magnet materials will continue to grow. At the same time, China has actively carried out technical innovation and industrialization of SmCo permanent magnet materials, and promoted the development of the industry in the direction of high-end, intelligent and green. From the technical point of view, with the continuous improvement of SmCo permanent magnetic material technology, its application field is also expanding, and it is expected to further improve the market competitiveness of SmCo permanent magnetic material in the future.

In the market, the demand for SmCo permanent magnetic materials will continue to grow. In recent years, with the rapid development of new energy vehicles, the application field of SmCo permanent magnetic materials has been expanding. According to the data of market research institutions, from 2018 to 2023, the annual composite growth rate of China's new energy vehicle market will reach about 30%, which will greatly promote the market demand for SmCo permanent magnet materials.

In addition, with the rise of 5G, new energy and other emerging industries, the application fields of SmCo permanent magnetic materials will continue to expand. At the same time, the Chinese government has also continuously increased its support for the samarium-cobalt permanent magnetic material industry, promoting the development of the industry in the direction of high-end, intelligent and green. Therefore, in the long run, the market of SmCo permanent magnet material has a broad prospect and has a large development potential and market space.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China