One of the structural characteristics of permanent magnet motors is the use of permanent magnet materials as the stator magnetic poles. The quality of this magnetic material directly affects the magnetic circuit size, volume, functional indicators, and motion characteristics of the motor. Permanent magnetic materials, also known as hard magnetic materials, are mainly characterized by high coercivity and high remanence. After saturation magnetization, they can maintain stable magnetism for a long time without the external magnetic field. These characteristics enable permanent magnet materials to establish a constant and stable magnetic field in the air gap, thereby achieving excitation work for permanent magnet motors.

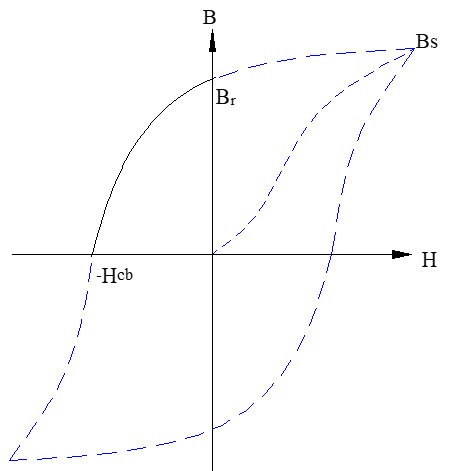

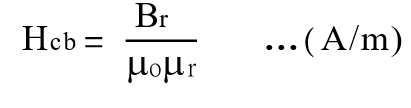

When the magnetization of the permanent magnet reaches a saturation state and the magnetic field strength H of the external magnetic field is gradually reduced to zero, the magnetic induction strength B of the permanent magnet will retreat from coercive induction strength Bs to residual magnetization Br. If the residual magnetic field Br is reduced to zero by applying a reverse magnetic field, the absolute value of the required reverse magnetic field strength is called the magnetic induced coercivity of the permanent magnet, abbreviated as the coercive force (Hcb), as shown in the following figure. By continuously and slowly changing the intensity of the external magnetic field for one cycle, a B-H closed magnetization curve can be formed. The part of this curve located in the second quadrant is called the demagnetization curve, which is the basic characteristic curve of permanent magnet materials and an important basis for marking the quality of permanent magnet materials.

In vacuum, the relationship between magnetic field intensity H and magnetic induction intensity B is B=0H. In magnetic materials, the relationship is B=0M+0H, where M is magnetization, in A/m, which is an important physical quantity of the degree of magnetization of permanent magnetic materials. 0 (equal to 4 π x10 ^ -7 H/m) is the Permeability of Vacuum.

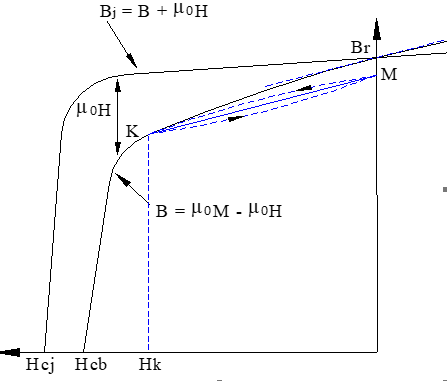

Due to the negative value of the magnetization magnetic field intensity H in the second quadrant, for convenience, we can reverse the H coordinate and define the demagnetization magnetic field intensity H as a positive value. Therefore, the relationship should be rewritten as B=0M0H. The above formula indicates that when H=0, B=Br=0M; When H=Hcb, B=0, while M=Hcb is a positive value and has not regressed to zero. To make M return to zero, it is necessary to continue increasing the demagnetized magnetic field intensity H until Hcj, as shown in the following figure. The curve Bj=B+0H is called the Intrinsic Demagnetization Curve. Bj is the intrinsic magnetic induction intensity of the permanent magnet material after magnetization, which is the intrinsic magnetic induction intensity, while Hcj is called the intrinsic coercive force.

When a permanent magnet is magnetized and the external magnetic field is removed, its magnetic density is Br. Under the strong effect of demagnetization, the magnetic density decreases along the demagnetization curve to a certain point, such as point K in the above figure. Then reduce the demagnetization effect until the field strength H=0. However, the magnetic density does not return to Br along the demagnetization curve, but rather reaches a lower point, such as point M. After adding the magnetic field strength to Hk, the magnetic density will follow a new curve to point K, forming a local small loop. Due to the small area of the loop, it can be approximately represented by a straight line KM, where KM is called the Recoil Line. The slope of the recovery line is called the recovery permeability, which is approximately equal to the slope at Br on the demagnetization curve, meaning that the recovery line is parallel to the tangent at Br on the demagnetization curve. R is an important parameter for the dynamic operation of permanent magnet materials. When r is small, permanent magnet materials have good dynamic performance.

Due to the different permanent magnetic circuits, the working points of the materials will also be different. The magnetic energy provided per unit volume of the material to the air gap is proportional to the product of the magnetic density B at the working point of the material and the magnetic field strength H, i.e. W=BH... (J/m3). According to this equation, when B=Br, H=0, W=0; When H=Hcb, B=0, W=0. The point D with the highest energy (BdHd) has the highest product, known as the maximum magnetic energy product (BH) max, which is the optimal operating point for permanent magnets (see figure below). For permanent magnet ferrite, the demagnetization curve of B=f (H) is generally a straight line, and the magnetic induction intensity can be written as: B=Br-0rH. When H=Hcb, B=0, substituted into the equation:

Since B=f (H) is a straight line, the value of (BH) max is located at the midpoint of the line, therefore

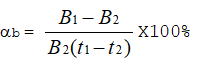

The temperature coefficient of magnetic induction (Temp. Coefficent of Br) ab, Curie Point (Tc), refers to the coefficient of reversible change of residual Br with temperature within the operating temperature range (generally -40 ℃ to+80 ℃):

In the formula, B1 and B2 are the magnetic induction strengths at temperatures t1 and t2, respectively.

The magnetic induction intensity of permanent magnet materials decreases with increasing temperature, therefore ab is a negative value. When the temperature rises to a certain value, the saturation magnetic induction intensity Bs decreases to zero, and the permanent magnet material loses its basic characteristics. This temperature is called the Curie point Tc (or Curie temperature). The smaller the temperature coefficient ab value, the better the temperature stability of permanent magnet materials; The higher the Curie point Tc, the higher the allowable temperature for use.

Due to different manufacturing processes, permanent magnet materials can be divided into two types: isotropic and anisotropic. In isotropic permanent magnets, the easily magnetized axes of different grains are disorderly oriented, so the residual magnetic Br is low, only about half of the saturation magnetic induction intensity Bs, and the corresponding maximum magnetic energy product (BH) max is also small. In contrast, in anisotropic permanent magnets, the easily magnetized axis of the grains is aligned along the direction of the formed magnetic field, and Br is close to Bs. Therefore, Br is about twice higher than isotropy, and for ferrite, (BH) max is nearly four times higher. Therefore, motor magnets typically use anisotropic materials.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China