The advantages of NdFeB Magnets in Aerospace and Defense

The Benefits of Using NdFeB Magnets in Magnetic Levitation Trains

The Future of Bonded NdFeB Magnets in the Automotive Industry

NdFeB magnets, also known as neodymium-iron-boron magnets, have a wide range of applications in the aerospace and defense industries. These magnets are composed of rare earth metals that provide exceptional magnetic strength and resistance to demagnetization, making them ideal for use in harsh environments.

One of the primary advantages of NdFeB magnets is their strength-to-weight ratio. This is particularly important in the aerospace industry, where weight restrictions and fuel consumption are major considerations. By using NdFeB magnets, aircraft can be designed to be more efficient, leading to significant cost savings in fuel and materials.

Another advantage of NdFeB magnets is their ability to provide precise control over the movement of objects. This is particularly important in weapons systems, where the accuracy of projectiles can mean the difference between success and failure. By using NdFeB magnets in guidance systems, military organizations can increase precision and reduce the risk of collateral damage in military operations.

Additionally, NdFeB magnets are highly resistant to corrosion, which is essential in military applications where exposure to harsh environments is common. They are used in a variety of applications including guidance systems, sensors, actuators, and generators. Their high-temperature stability and resistance to demagnetization make them ideal for use in engines, powertrains, and other critical components.

In the defense industry, NdFeB magnets are used in a wide range of applications, including electronic warfare, missile guidance, and navigation systems. They are also used in the production of military aircraft and submarines, where their high strength and resistance to corrosion make them essential for critical components.

NdFeB magnets are relatively affordable compared to other high-performance magnets like samarium cobalt (SmCo). While SmCo magnets have similar magnetic properties, they are significantly more expensive, making NdFeB magnets a popular choice in many applications.

The first permanent magnetic levitation air rail test line in China, "Red Rail", was successfully completed in Xingguo County, Ganzhou, Jiangxi Province. This is a new type of rail transit, which will further improve the comprehensive transportation network and greatly reduce environmental pollution and carbon emissions on the planet. Using rare earth alloys to reduce costs is of great significance for new rail transit systems

In particular, the permanent magnet used is neodymium iron boron alloy, which is a rare earth permanent magnet alloy material suitable for magnetic levitation transportation systems. It has characteristics such as strong magnetism, stable magnetism, reasonable magnetic energy distribution, and high natural reserve abundance of rare earth elements neodymium and boron, thereby greatly reducing costs.

According to the principle of magnetic levitation, the main magnetic levitation technologies are generally divided into permanent magnetic levitation, electromagnetic levitation, electric levitation, and superconducting pinning levitation.

The application of electromagnetic suspension and electric suspension technology has reached a high degree of maturity; High temperature superconducting pinning suspension started relatively late and is still in the stage of laboratory research and engineering prototype vehicle development; The permanent magnetic suspension technology used in "Red Rail" is the current research focus.

The "Red Rail" test line can suspend the train without using electricity, which is quite energy-saving and environmentally friendly.

Its manufacturing materials have also made new breakthroughs in the field of magnet materials, not only achieving recycling, but also producing permanent magnets with small volume, high magnetic energy density, sufficient levitation force, and good economy. Therefore, the permanent magnet floating air rail project explores a medium to low volume, personalized, and intelligent transportation mode that can adapt to complex terrain.

The "Red Rail" test line, which successfully launched this time, is most unique in that it has achieved the first integration of rare earth permanent magnet magnetic levitation technology and air rail technology in the world to build a new system of rail transit with medium to low speed and medium to low traffic capacity.

Moreover, the cost advantage of this rare earth permanent magnet maglev test line is significant - compared to subways, intercity railways, and other suspension systems, the cost of rare earth permanent magnet maglev trains is only about 1/2 of that of light rail, with a construction cost of less than 100 million yuan per kilometer, which is one-third of the cost of today's medium and high speed maglev transportation systems. If it is scaled up in the future, its cost should still be lower.

With their ability to provide precise control over the movement of objects, resistance to corrosion, and affordability, NdFeB magnets are increasingly becoming the go-to choice for high-performance applications in various industries.

SEO Description: NdFeB magnets are a powerful and versatile type of rare earth magnet that provides exceptional magnetic strength and resistance to demagnetization. They are ideal for use in harsh environments, making them crucial components in high-tech industries such as aerospace, defense, transportation, and automotive.

SEO Keywords: NdFeB magnets, rare earth magnets, aerospace, defense, transportation, automotive, magnetic strength, resistance to demagnetization, harsh environments, high-tech industries.

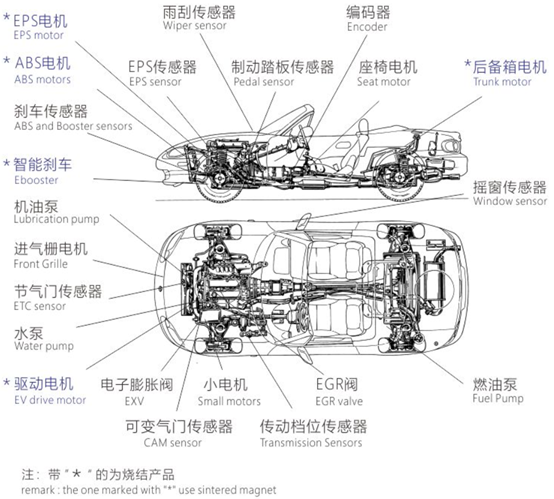

Neodymium, iron, and boron play an extremely important role in the modern automotive industry. Due to their high magnetic field strength and high efficiency, these magnets are widely used in electric motors, generators, regenerative braking systems, and automotive electronics.

In electric motors and generators, neodymium iron boron magnets have already become an indispensable component. They can provide higher output power and lower energy consumption, making electric motors and generators more portable and flexible, significantly improving vehicle performance. Recent research has shown that the use of neodymium iron boron magnets in electric motors and generators has a significant effect, so its application prospects in this field are very broad.

In addition to electric motors and generators, the use of neodymium iron boron magnets in regenerative braking systems is also very common. Regenerative braking systems can convert kinetic energy into electrical energy, thereby improving the energy-saving performance of vehicles. Neodymium iron boron magnets play a very important role in this process, making the regenerative braking system more efficient and energy-saving through their high efficiency and strong magnetic force.

Neodymium iron boron magnets are also widely used in automotive electronics. For example, they can be used to manufacture important components such as safety information systems, electronic control units, vehicle multimedia systems, and energy transmission systems. Due to its high strength and stability, neodymium iron boron magnets make these systems more reliable and effective, and provide good self lubricating performance.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China