Ferrites generally refer to composite oxides of iron group and one or more other appropriate metal elements. They belong to semiconductors and are used as magnetic media. Ferrite is a kind of metal oxide with ferromagnetism. In terms of electrical properties, the resistivity of ferrite is much higher than that of metal and alloy magnetic materials, and it also has higher dielectric properties. The magnetic properties of ferrite also show high permeability at high frequency. Therefore, ferrite has become a widely used non-metallic magnetic material in the field of high-frequency and weak current. Due to the low magnetic energy stored in the unit volume of ferrite and the low saturation magnetization (usually only 1/3~1/5 of that of pure iron), its application in low-frequency strong current and high-power fields requiring high magnetic energy density is limited. The main characteristic of ferrite magnetism is that the resistivity is far greater than that of metal magnetic materials, which inhibits the generation of eddy current and makes the magnetic properties of ferrite applied to high-frequency fields. The wave absorbing property of ferrite is derived from its ferrimagnetism and dielectric properties. Its relative permeability and relative conductivity are in the form of complex numbers. It can produce both dielectric loss and magnetic loss. Therefore, ferrite wave absorbing materials have good microwave properties.

Soft magnetic ferrite includes manganese ferrite (MnO · Fe2O3), zinc ferrite (ZnO · Fe2O3), nickel zinc ferrite (Ni-Zn · Fe2O4), manganese magnesium zinc ferrite (Mn-Mg-Zn · Fe2O4) and other single-component or multi-component ferrite. The resistivity is much larger than that of metal magnetic materials, and has higher dielectric properties. Therefore, ferrites with both ferromagnetic and ferroelectric properties and ferromagnetic and piezoelectric properties appear. At high frequencies, it has much higher permeability than metal magnetic materials (including Fe-Ni alloy and Al-Si-Fe alloy), and is suitable for working at frequencies from several thousand to several hundred megahertz. The processing of ferrite belongs to the general ceramic process, which is simple, saves a lot of precious metals and has low cost.

The saturation magnetic flux density Bs of ferrite is low, usually only 1/3~1/5 of that of iron. The low magnetic energy stored by ferrite in unit volume limits its application in low frequency, strong current and high power fields requiring high magnetic energy density. It is more suitable for high frequency, low power and weak current applications. Ni-Zn ferrite can be used as antenna magnetic rod and IF transformer core in radio, and Mn-Zn ferrite can be used as line output transformer core in TV receiver. In addition, soft ferrite is also used for the magnetic core of the inductor and filter in the communication line. In recent years, it is also used as high-frequency magnetic recording transducer (magnetic head).

The hard ferrite includes barium ferrite (BaO · 6Fe2O3) and strontium ferrite (SrO · 6Fe2O3). It has high resistivity and belongs to semiconductor type, so it has low eddy current loss and high coercivity. It can be effectively applied in the magnetic circuit of the air gap, especially suitable for hard magnets of small generators and motors. It does not contain precious metals such as nickel and cobalt. It has rich sources of raw materials, uncomplicated process and low cost. It can replace Al-Ni-Co hard magnets. Its maximum magnetic energy product (B+H) m is low, so it is larger than metal magnets under the condition of equal magnetic energy. It has poor temperature stability, brittle and fragile texture, and is not resistant to shock and vibration. It is not suitable for measuring instruments and magnetic devices with precision requirements. Hard magnet ferrite products are mainly anisotropic series. They can be used to make hard magnet ignition motors, hard magnet motors, hard magnet mineral separators, hard magnet suspension heads, magnetic thrust bearings, magnetic separators, loudspeakers, microwave devices, magnetic therapy films, hearing aids, etc.

According to the different production processes, the hard magnet ferrite is divided into two types: sintering and bonding. The sintering is divided into dry compression type and wet compression type, and the bonding is divided into extrusion molding, compression molding and injection molding. According to whether the external magnetic field is applied during forming, it can be divided into isotropic hard magnets and anisotropic hard magnets. The magnetic properties of isotropic sintered ferrite hard magnet materials are weak, but they can be magnetized in different directions of the magnet; Anisotropic ferrite hard magnetic materials have strong magnetic properties, but they can only be magnetized along the predetermined direction of magnetization. The soft, elastic and twisted magnet made of bonded ferrite powder and synthetic rubber is also called rubber magnet.

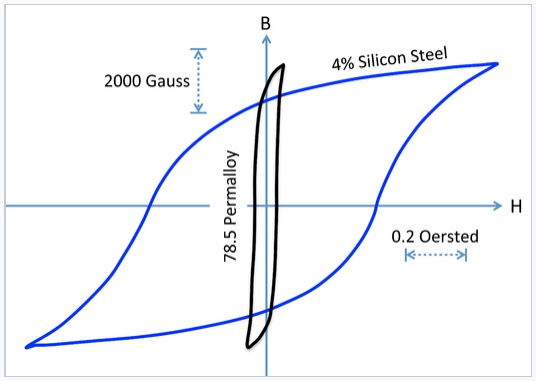

Soft magnetic material | Hard magnetic material |

Smaller material surrounded by hysteresis loop | Material with large area surrounded by hysteresis loop |

With low remanence | With high remanence |

With low coercivity | With high coercivity |

High initial permeability | Low initial permeability |

Lower hysteresis loss | Higher hysteresis loss |

Low eddy current loss | Metal type has more eddy current loss, while ceramic type has lower eddy current loss |

The figure above compares the hysteresis loops of hard and soft magnets. The energy dissipated during material magnetization and demagnetization is proportional to the area of the hysteresis loop. We can see that although the soft magnet can reach a high Bsat value, it consumes relatively less energy in the circuit. This makes the soft magnet more suitable for the transformer core for fast switching of magnetic field.

Appearance

Ferrite: ferrites are loose and have no metallic luster, generally not electroplated, usually black.

NdFeB, iron and boron: NdFeB, iron and boron should be basically electroplated, otherwise it is easy to rust. The surface has silver white metallic luster.

Magnetic force

Ferrite: The magnetic force of ferrite is usually 800-1000 Gauss, and the density is 5 (g/cm3);

NdFeB: In the state of bare magnetism, the magnetic force of NdFeB can reach about 3500 gauss. The density is 7.5 (g/cm3);

Performance

Ferrite: The temperature resistance and stability of ferrite are very good, compared with the ordinary temperature resistance of NdFeB iron boron is only 80 degrees.

NdFeB: NdFeB has the characteristics of small size, light weight and strong magnetism. Its magnetism is completely different from that of ferrite.

Price

Ferrite: Ferrite is usually cheap, many of which are calculated by pieces, and the price has an impact on the shape, size and processing difficulty of ferrite.

NdFeB: The price of NdFeB, iron and boron changes almost every day, depending on the brand and special requirements used.

Hard magnetic ferrite has the characteristics of high coercivity and low remanence in performance. The hard magnetic ferrite has large coercivity and strong anti-demagnetization ability, and is suitable for working in the dynamic magnetic circuit environment with large temperature changes.

The hard magnetic ferrite material is hard and brittle, and can be cut with emery tools.

The main raw material is oxide, so it is not easy to corrode and generally does not need coating.

Working temperature: - 40 ℃ to+300 ℃.

Note: Ferrites and NdFeB magnets also have different disadvantages. Ferrite magnets are very fragile and easily broken. They cannot be used on machinery that is under great pressure or bending. If exposed to high temperatures (more than 480 degrees Fahrenheit), they will be demagnetized. They only have medium-strength magnetic fields and are not suitable for applications requiring strong magnetic fields. NdFeB magnets are relatively expensive than ferrite magnets. They are easy to rust, and additional measures must be taken to protect them from corrosion. NdFeB magnets are also very fragile and will break under pressure. If exposed above 175 to 480 degrees Fahrenheit (depending on the alloy used), they will lose their magnetism.

China is a major producer of magnetic materials, accounting for more than 60% of the world's output, followed by Japan, South Korea, India and Vietnam. According to statistics, in 2021, China's sales of magnetic materials will be about 1.3 million tons, including 800000 tons of hard magnet ferrite, accounting for 60%, 200000 tons of rare earth hard magnets, accounting for 15%, 300000 tons of soft magnet ferrite, accounting for 23%, and 30000 tons of other magnets, accounting for 2%.

With the development of new technologies such as automobile power and environmental protection technology, safety and comfort, hard magnet ferrite DC motor has been widely used in three parts and accessories of automobile engine, chassis and body, such as starting motor, electric antenna motor, wiper motor, window motor, air purification motor, electric seat, ABS motor, fan motor, etc. According to statistics, the demand for hard magnet ferrite in China's automobile industry will be 420000 tons in 2021, and it is expected to reach 614000 tons in 2025. With the improvement of automobile intelligence and automation, the number of DC motors with hard magnet ferrite in single vehicle will increase significantly, especially for new energy vehicles.

In general, the development of China's hard magnet ferrite material industry is relatively stable, but the changes in supply and demand in the international peripheral markets and the price fluctuations of raw materials will also have a certain impact on the industrial development. At present, the production of hard magnet ferrite in China has been quite mature and developed, but most of our magnetic material products are concentrated in the middle and low level.

In the future, the technical development direction of hard magnetic ferrite products in China will be La-Co, La-Zn and magnetic particle size distribution control technology, high orientation technology and special process technology. Should develop:

SrM magnet with higher magnetic performance;

Hard magnetic ferrite material with higher temperature stability;

Smaller and thinner hard ferrite magnet;

High-precision dimensional and geometric tolerance hard magnet ferrite products;

Diversified magnetization methods (multipolar anisotropic radial magnetization, two-stage anisotropic radial magnetization, radiation orientation anisotropy) hard magnet ferrite products;

Hard-magnet ferrite products with wider application fields.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China