A magnetic separator is a device that utilizes the magnetic differences between minerals for sorting, playing various roles in improving ore grade, purifying solid liquid materials, and recycling waste. In the industry, magnetic separators are one of the most widely used and versatile machines.

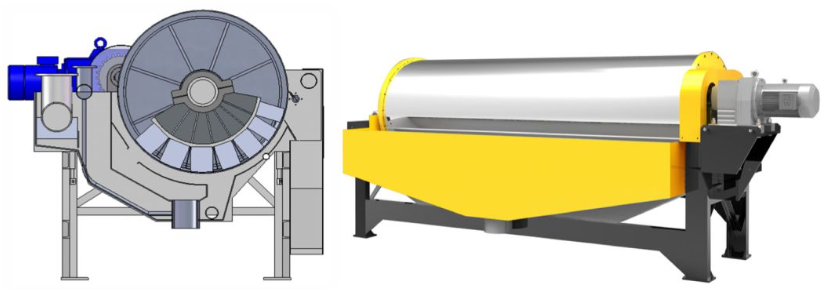

In recent years, with the increasingly mature research on the magnetic circuit of permanent magnet magnetic separators and the emergence of high-performance permanent magnet materials, rapid development has been made in the development of permanent magnet magnetic separation equipment, and permanent magnet magnetic separators have been widely used in many fields. In order to meet the practical needs of modern socialized industrial production, magnetic separation equipment is gradually becoming larger in scale, and the body structure is gradually becoming diversified, complex, and lightweight. The specifications are gradually serialized, and the control methods are gradually realizing automatic program control and monitoring. In the application of permanent magnet magnetic separators in actual industrial production, with the rapid development of body materials, processing accuracy, and magnetic properties of magnetic materials, and due to the advantages of simple body, stable performance, energy conservation, and convenient installation, the two series of permanent magnet magnetic separators, permanent magnet magnetic drum and permanent magnet cylindrical magnetic separator, have been widely used in fields such as mining, power, coal, and paper making.

Taking the wet permanent magnet cylindrical magnetic separator as an example, the magnetic separator mainly consists of six components: cylinder, roller, brush roller, magnetic system, slot body, and transmission part. Among them, the cylinder is a cylinder made of 2-3mm stainless steel plate rolled and welded, and connected to the end cover (aluminum casting or workpiece) through stainless steel screws. The motor drives the rotary motion of the cylinder, magnetic roller, and brush roller through a reducer or directly using a stepless speed control motor.

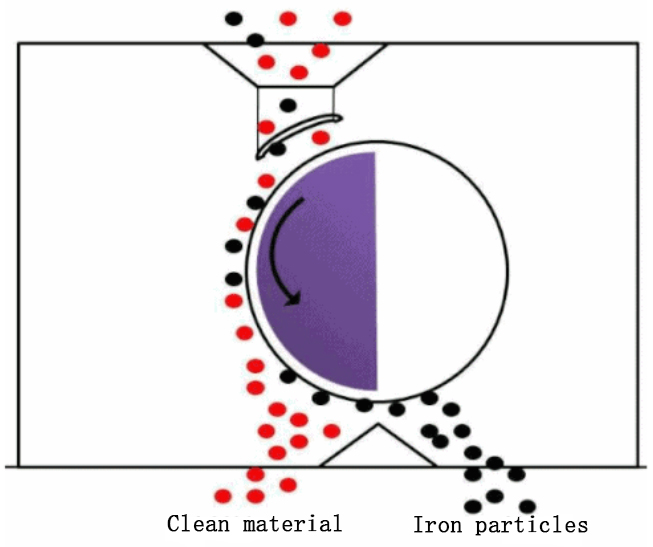

After the ore slurry flows into the trough of the magnetic separator, the ore particles enter the feeding area of the trough in a loose state through the water flow of the feeding spray pipe. Under the action of a magnetic field, magnetic ore particles will undergo magnetic agglomeration, forming so-called "magnetic clusters" or "magnetic chains", and be adsorbed on the cylinder with the action of magnetic force. Due to the alternating polarity of the magnetic poles along the rotation direction of the cylinder and being in a fixed state during operation, the phenomenon of magnetic stirring occurs when the "magnetic cluster" or "magnetic chain" rotates with the cylinder due to the alternating dislocation of the magnetic poles. This stirring action will cause non magnetic minerals such as gangue mixed in "magnetic clusters" or "magnetic chains" to fall off during flipping, and ultimately the "magnetic clusters" or "magnetic chains" adsorbed on the surface of the cylinder become the concentrate. When the concentrate rotates to the edge of the magnetic system with the cylinder, where the magnetic force is weakest, the flushing water will spray it out of the unloading water pipe and flush it into the concentrate tank. Non magnetic or weakly magnetic minerals will remain in the slurry and be discharged together with the slurry to form tailings outside the tank.

Magnetic separators have multiple classification methods based on different characteristics and standards.

According to the strength of the magnetic field and the strength of the magnetic force, it can be divided into:

Weak magnetic field separator: The magnetic field strength of the working gap is (0.6~1.6) × 105A/m, used to select strong magnetic minerals;

Medium magnetic field separator: The magnetic field strength of the working gap is (1.6-4.8) × 105A/m, used to select medium magnetic minerals;

Strong magnetic field separator: The magnetic field strength of the working gap is (4.8~20.8) × 105A/m, used to select weakly magnetic minerals.

According to the selected medium, it can be divided into:

Dry magnetic separator: used for air separation, mainly for separating large and coarse strong magnetic ores and fine weak magnetic ores. Currently, efforts are also being made to separate fine-grained strong magnetic ores;

Wet magnetic separator: used for separation in water or magnetic liquids. Mainly used for separating fine-grained strong magnetic ores and fine-grained weak magnetic ores.

In addition, classification can also be carried out based on the way magnetic ore particles are selected, the direction of movement of the feeding material, the method of discharging selected products from the selection zone, and the structural characteristics of the discharged magnetic products.

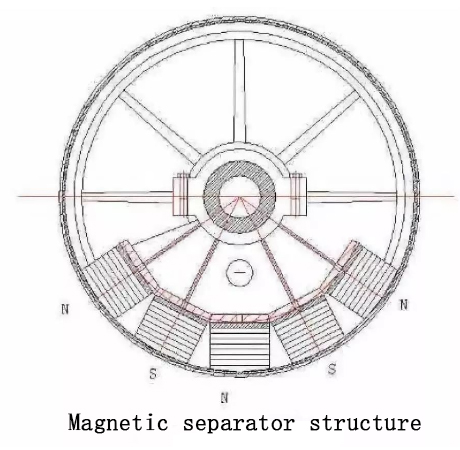

The closed circuit formed by the convergence of magnetic flux lines is called a magnetic circuit, and the magnetic system of a magnetic separator needs to generate a certain strength of magnetic field, and most of the magnetic flux lines need to be able to concentrate through the sorting space. The height, width, radius, and number of poles of the magnetic system, the magnetic potential difference, pole distance, the ratio of pole surface width to pole gap width between adjacent poles, the shape of the magnetic poles and their end faces, and the distance from the magnetic pole end face to its arrangement center can all affect the magnetic field characteristics.

Taking the magnetic separator shown in this figure as an example, the magnetic circuit adopts a five pole magnetic system. Each magnetic pole is bonded by ferrite and NdFeB permanent magnet blocks, and is fixed on the magnetic guide plate by screws passing through the center hole of the magnetic block. The magnetic guide plate is fixed on the axis of the cylinder through a bracket, and the magnetic system is fixed, while the cylinder can rotate. The polarity of the magnetic poles is arranged alternately along the circumference, with the same polarity along the axis. The drum is sheathed outside the magnetic system and is made of stainless steel non magnetic material. The use of non magnetic material is to avoid magnetic field lines from entering the selected zone through the cylinder and forming a magnetic short circuit with the cylinder. In the vicinity of the magnetic system, the slot body should also be made of non magnetic materials, while the rest can be made of ordinary steel plates or hard plastic sheets.

The performance characteristics of a permanent magnet separator mainly depend on the quality of the permanent magnet component. Permanent magnets typically have fixed dimensions (such as long × wide × High=85 × sixty-five × 21 millimeters, therefore also known as permanent magnet blocks or magnetic blocks. The permanent magnet materials required for producing the magnetic system of the magnetic separator include permanent magnet ferrite, aluminum nickel cobalt, iron chromium cobalt and manganese aluminum iron, samarium cobalt permanent magnet materials, and NdFeB permanent magnet materials. In domestic magnetic separation equipment, permanent magnet ferrite (such as strontium ferrite and barium ferrite) is the most commonly used permanent magnet material, followed by NdFeB permanent magnet material. Therefore, it can be said that for permanent magnet separators, permanent magnets are the most critical component, and their quality will directly affect the performance of the magnetic separator.

When designing the magnetic system, it is necessary to select suitable permanent magnet materials based on specific circumstances, mainly considering the following factors:

Magnetic field strength: In order to generate a stable magnetic field within the specified workspace, it is necessary to choose a permanent magnet material with appropriate magnetic field strength. Generally speaking, NdFeB permanent magnet materials have better magnetic properties than ferrite.

Magnetic field stability: It is necessary to consider the impact of environmental factors on permanent magnet materials, such as temperature, humidity, vibration, and impact. Choosing permanent magnet materials with stronger adaptability can improve the long-term stability of the magnetic field.

Mechanical properties: The toughness, flexibility, and compressive strength of permanent magnet materials can also affect the design of magnetic systems. Choosing permanent magnet materials with good mechanical properties can improve the stability and lifespan of magnetic systems.

Price factor: The cost of permanent magnet materials is also an important factor to consider when formulating magnetic system design plans. According to the budget situation, selecting permanent magnet materials with moderate cost and good performance can achieve optimization of cost-effectiveness.

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: sales1@atmsh.com

Add: No.6 Huxiang Road, Kunshan development Zone, Jiangsu

Shanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China