Basic MIM Design Guide

BRM is specialized in metallic materials and serves for emerging industries of strategic importance. it provides its high-end global customers with the advanced metallic materials, products and solutions to their materials technology problems in businesses covering Metallurgy, Magnetic Materials, Amorphous, Nanocrystalline products, Refractory materials & products, filtration materials & environment protection engineering, high speed and diamond tools. Group company was established in the Zhongguancun Science Park in December 1998, and underwent a successful IPO issuing 60 million of a share on Shenzhen Stock Exchange, the registered capital has been CNY 863 million by December 2015. Group has already established four production bases in the Yongfeng, Konggang and Changpin, and owns 18 holding companies, we have set up comprehensive market channel and technology cooperation by many well known enterprises in the worldwide and exported to more than 50 countries and regions. |

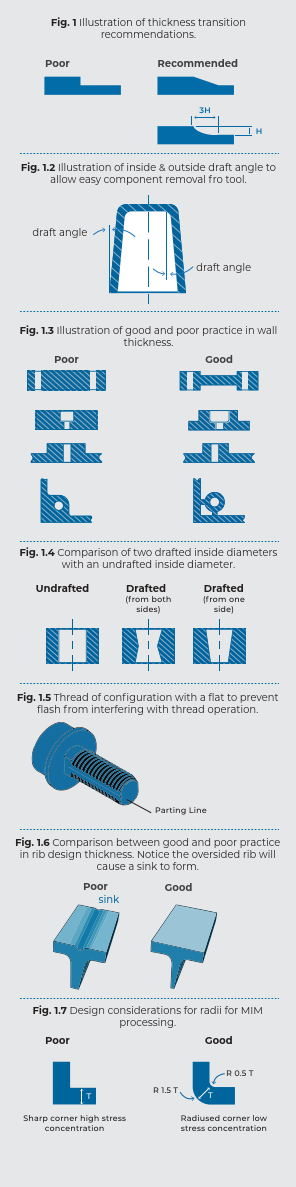

Design Do’s | Design Dont’s |

Maintain uniform wall thickness Core out thick areas Design with a flat surface, lettering and threads Consider location of gates, ejector pins, and parting lines. | Walls should be no thinner than 0.1mm (0.0039 in.) Don’t design holes smaller than 0.1mm (0.00e9 inc) in diameter Dont design components over 12.55 mm (0.5 in.) thick and over 100 grams in mass Avoid designing sharp corners |

Typical Attributes Produced by the MIM Process | |||

Attribute | Minimum | Typical | Maximum |

Component Mass (g) | 0.030 | 10-15 | 300 |

Max Dimension (mm) | 2 (0a.08 in) | 25 (1 in) | 150 (6 in) |

Min Wall Thickness (mm) | 0.025 (0.001 in)* | 5 (0.2 in) | 15 (0.6 in) |

Tolerance (%) | 0.2% | 0.5% | 1% |

Density | 93% | 98% | 100% |

Production Quantity | 1000 | 100,000 | 100,000,000 |

MIM Structural Material Properties | |||||||

Material | Density (g/cc) | YS (MPa) | UTS (MPa) | Elongation (%) | Unnotched Charpy Impact Energy (J) | Macro Hardness | Young’s modulus (GPa) |

316L SS | 7.8 | 180 | 520 | 40 | 190 | 67 HRB | 185 |

17-4PH SS | 7.6 | 740 | 900 | 6 | 140 | 27 HRC | 190 |

17-4PH SS H900 | 7.6 | 1100 | 1200 | 4 | 140 | 33 HRC | 190 |

420 SS | 7.5 | 1200 | 1370 | 40 | 44 HRC | 190 | |

440C SS | 7.6 | 1600 | 1250 | 1 | 55 HRC | 190 | |

310 SS | 7.5 | 185 | |||||

Fe | 7.6 | 20 | 190 | ||||

2200(2Ni) | 7.6 | 125 | 280 | 35 | 135 | 45 HRB | 190 |

2700(7.5 Ni) | 7.6 | 250 | 400 | 12 | 175 | 69 HRB | 190 |

4605 | 7.55 | 210 | 440 | 15 | 70 | 62 HRB | 200 |

4605HT | 7.55 | 1480 | 1650 | 1 | 55 | 48 HRC | 210 |

4140HT | 7.5 | 1200 | 1600 | 5 | 75 | 46 HRC | 200 |

Contact: Cindy Wang

Phone: +86 19916725892

Tel: 0512-55128901

Email: [email protected]

Add: No.6 Huxiang Road, Kunshan development Zone, JiangsuShanghai Branch: No. 398 Guiyang Rd, Yangpu District, Shanghai, China